Tribology

Tribology for industrial performance

Tribology, the science dedicated to studying friction, wear, and lubrication phenomena between contacting materials, is a long-standing expertise within IREIS and the HEF Group. This discipline enables us to respond to a multitude of industrial needs, offering solutions adapted to the specific requirements of each field. Surface treatments, such as texturing or the application of DLC (diamond-like carbon) coatings, aim to optimize performance based on the desired function: reducing friction, increasing wear resistance, or enhancing friction to ensure secure assembly retention. The applications of tribology are extensive, spanning diverse industries including aerospace, automotive, medical, construction, and everyday tools.

Tribology for extreme challenges

Tribology, due to the diversity of situations in which friction plays a crucial role, requires in-depth expertise to address the varied challenges encountered across many industrial sectors. The HEF Group, with its recognized expertise, considers a wide range of parameters such as materials (metals, polymers, ceramics), types of lubricants (oils, greases), and extreme operating conditions (pressures ranging from 10⁻⁵ mbar to 35 bar, temperatures from -200°C to +700°C, gaseous or liquid environments, and speeds up to several tens of meters per second). In addition to these factors, contact geometry, applied loads, and surface properties (hardness, roughness, chemical composition, geometric defects, and lubricant affinity) also influence tribological behavior.

Tribological optimization: the IREIS solution for enhanced performance

In this context, IREIS develops specialized coatings to optimize tribological performance, in particular by reducing friction between materials. Using state-of-the-art equipment, IREIS is able to reduce energy loss and temperature rise, achieving friction coefficients of less than 0.1 under specific operating conditions, such as mixed or EHD (elasto-hydro-dynamic) operation with DLC layers in a lubricated environment. The study of surface texturing—especially through laser technology—further enhances these properties, with broad applications in areas like aerodynamics, aiming to reduce air friction. By combining the expertise of the HEF and IREIS teams, comprehensive and tailored tribological solutions can be offered to address specific challenges.

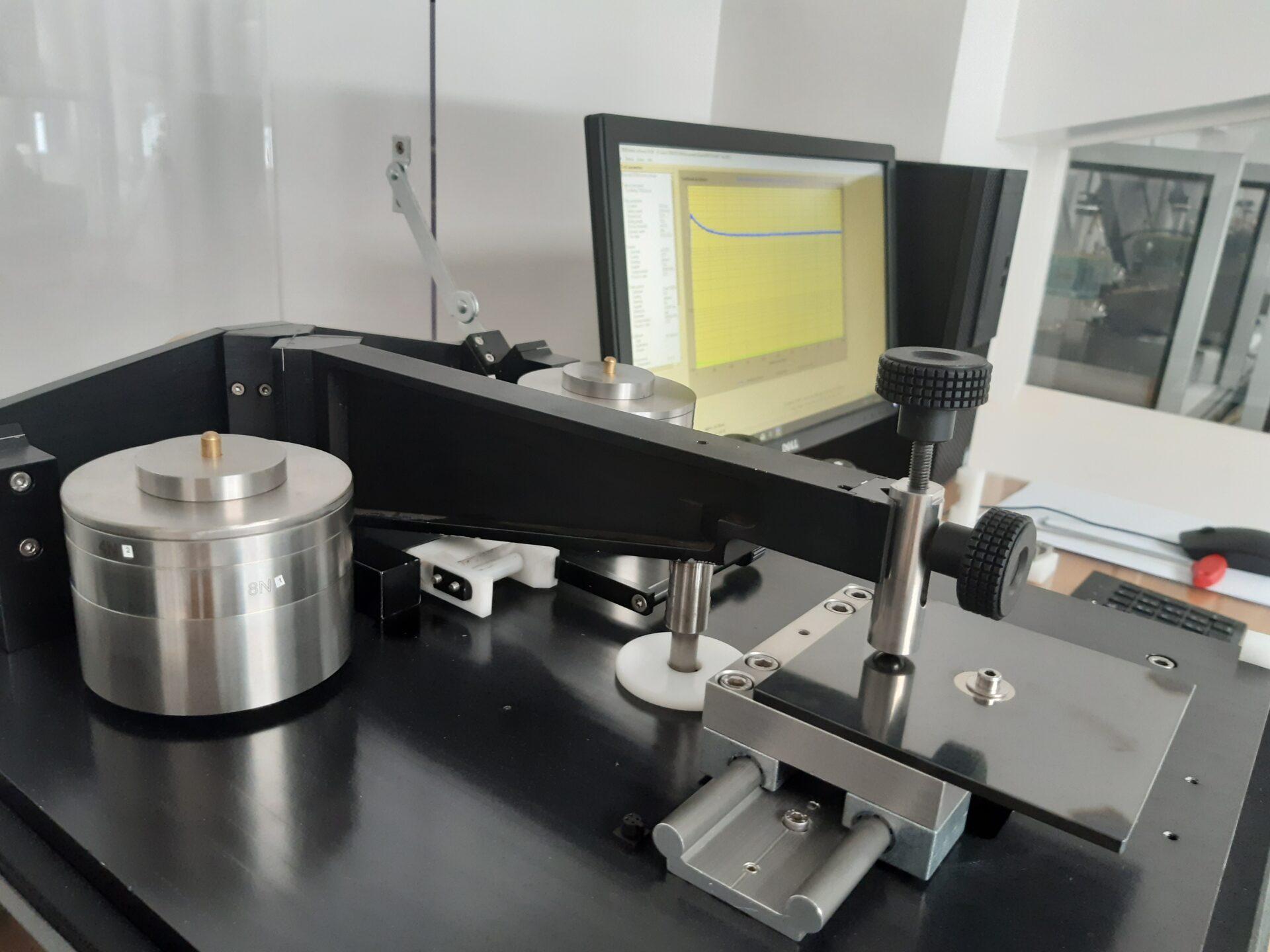

IREIS Test Benches

IREIS has a fleet of over twenty permanent test benches dedicated to friction and wear testing, and can customize or even design specific test rigs upon request. Since the founding of the HEF group, more than 2,000 tribological studies have been conducted, enabling the development of a unique expertise in this specialized field.

IREIS expertise in coatings and surface structuring

Assembling multi-material systems is becoming increasingly common to meet requirements for lightweighting, aesthetics, and added functionality. IREIS develops and refines coatings applied using vacuum deposition, thermal spraying, or electroplating. IREIS is also working on surface structuring to optimize the mechanical strength and properties of multi-material assemblies achieved through physical processes (brazing, riveting, screwing, etc.) or chemical processes (bonding). These solutions increase the coefficient of friction between surfaces or enhance the wettability of filler materials.