Laser

Ultra-fast laser processing: a high-performance technological opportunity

Ultra-fast laser processing, especially using Femtosecond Laser technology, opens new opportunities for functionalization, texturing, and micro-machining of materials in both 2D and 3D.

This method enables fast, precise treatment without thermal damage. It can be applied to a wide variety of materials, from the hardest to the most fragile.

Our processes guarantee extreme precision, perfect thermal control, optimal reproducibility, and require no post-processing.

They adapt to various geometries, from flat surfaces to complex shapes, and to part sizes ranging from micrometers to square meters.

Material removal is carried out without burrs or thermal impact, ensuring strict dimensional control.

Operationally, our ultra-fast laser solutions offer high productivity and cost optimization.

They also enhance the intrinsic performance of materials.

This technology has a low carbon footprint thanks to limited electrical consumption and a contactless technique without additives or consumables.

Our teams of experts translate scientific advances into concrete industrial applications.

Main Applications

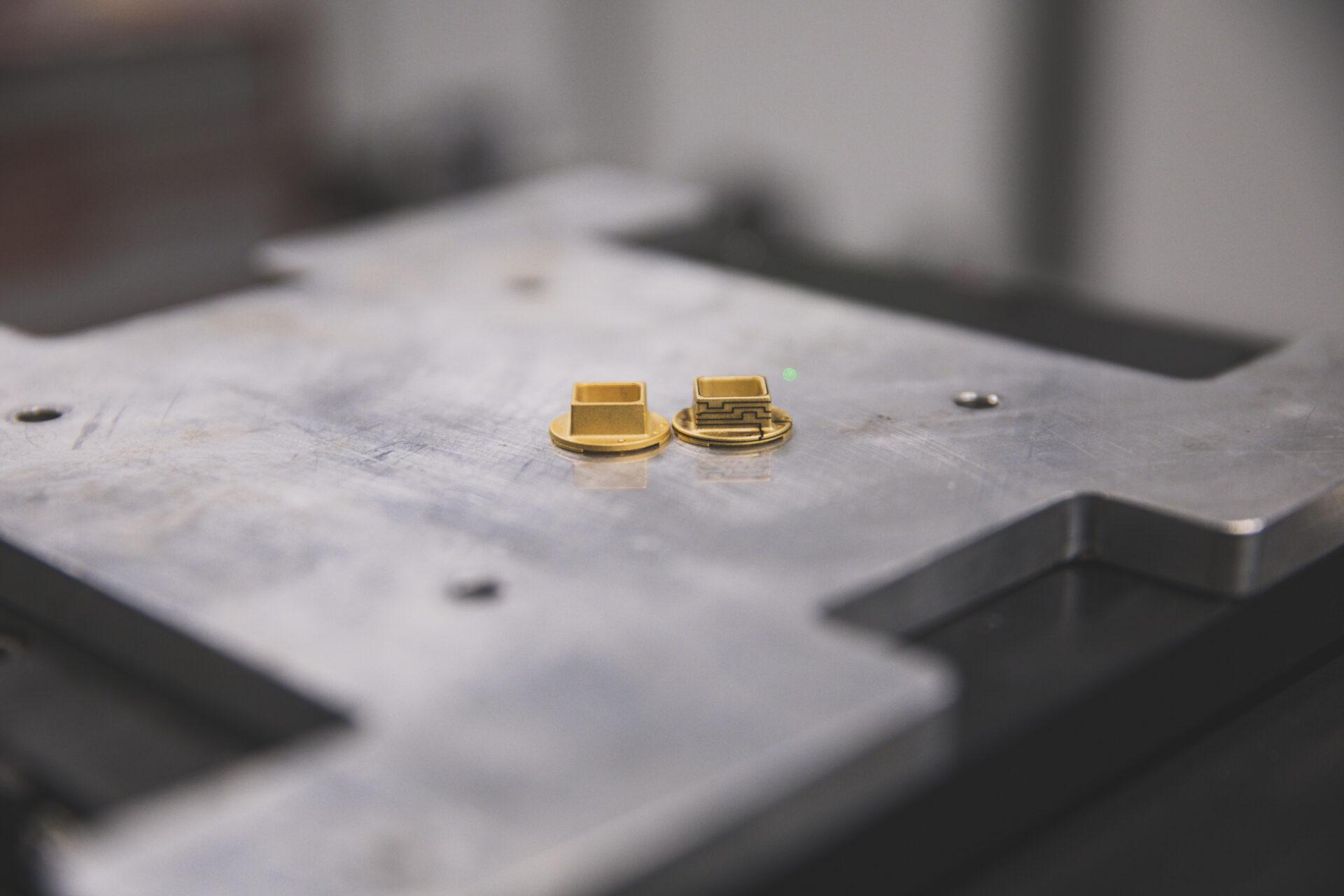

Engraving

Ultra-fast laser technology enables precise engraving at high speeds (mm³/s), with surface roughness below one micrometer, without damaging the material, in both 2D and 3D.

Femtosecond lasers provide optimal thermal control and preserve material quality.

This technique is ideal for creating microchannels, tribology applications, sealing, or aesthetic effects.

Micro and Nano-Texturing

Texturing modifies the surface’s structural properties to provide specific technical functionalities.

It is performed by high-speed, high-resolution ablation without material damage, in 2D and 3D.

This process allows the creation of nanometric surfaces with features such as:

wettability (hydrophobic, hydrophilic), sealing, frost resistance, improved tribology (friction, adhesion), conductivity, or coloration effects (deep black, iridescence).

Cutting and Drilling

The laser enables the creation of very fine holes (down to 10 µm in diameter) in glass, metals, or plastics.

Through-cutting of materials up to 1 mm thick is done at high speed.

Thermal management ensures clean cut edges without burrs, preserving the substrate.

Selective Thin-Film Ablation

This technique, called “decoating,” allows selective removal of thin layers without damaging the substrate.

It prevents burrs and micro-cracks.

Applications

Femtosecond laser applications are already deployed in demanding industrial sectors such as aerospace, defense, energy, and electronics.

Inspired by biomimicry, this technology replicates efficient natural structures.

For example, shark skin to improve hydrodynamics, lotus leaves for hydrophobic surfaces, or gecko feet for optimized adhesion.