Decarbonized energies

IREIS's commitment to sustainable energy

The energy sector is a major market where every improvement in efficiency leads to significant reductions in energy losses, generating both economic and environmental benefits. IREIS focuses in particular on studying friction in bearings used in hydraulic turbines for nuclear and hydroelectric power plants. Our technologies and coatings are also applied in the field of renewable energy, including the development of coatings to improve light absorption in solar thermal power plants or to reduce friction and increase wear resistance in wind turbines.

IREIS is also active in addressing energy storage challenges by supporting research on alternative materials for batteries and fuel cells, aiming to meet economic and environmental requirements while optimizing the performance of these systems.

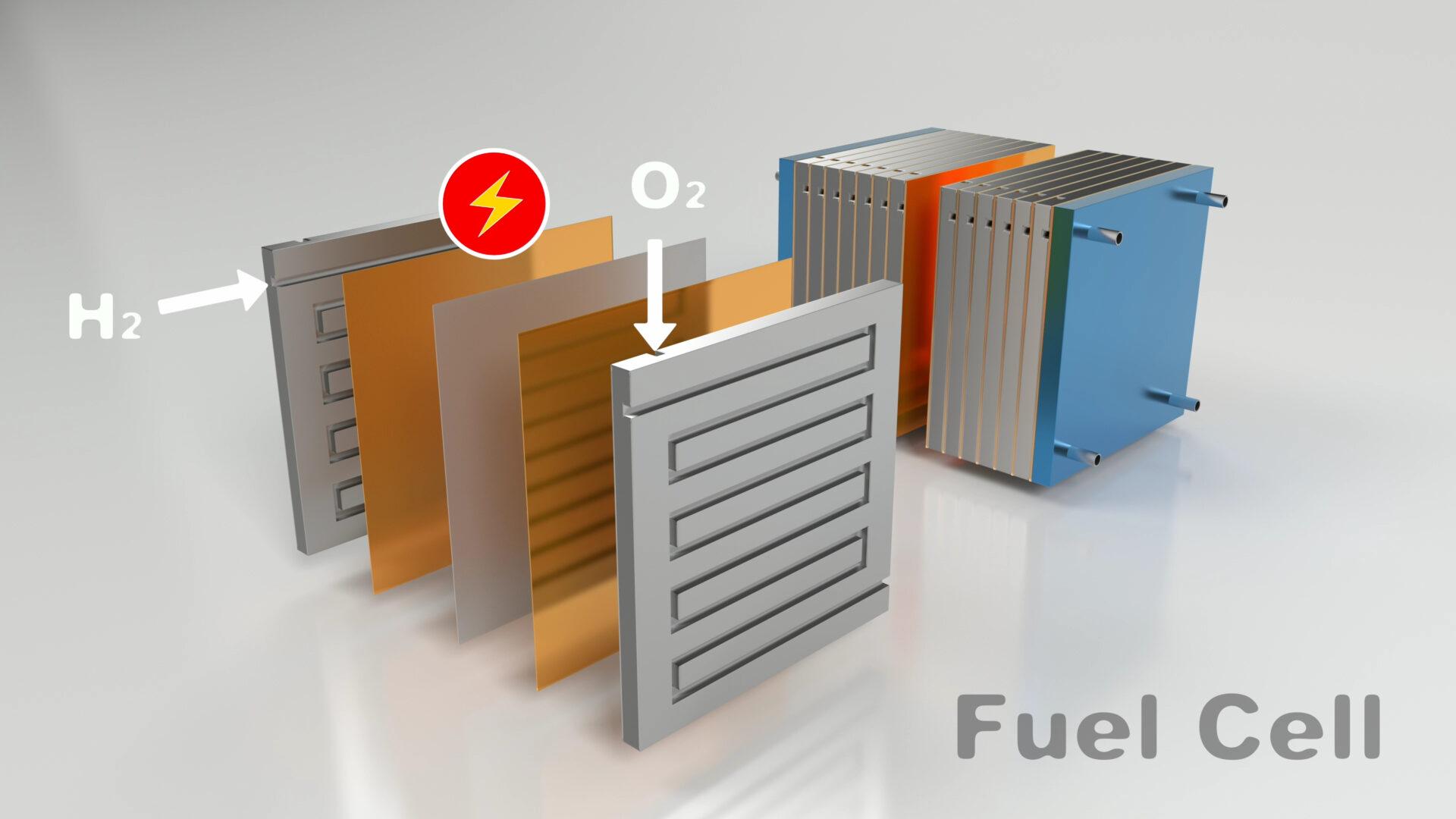

Fuel cells

Fuel cells offer many advantages and are often considered an efficient solution for producing electricity from hydrogen. However, to ensure performance and durability, the components must be protected against corrosion. IREIS develops coatings specifically designed to protect bipolar plates and optimize their electrical conductivity. These coatings are essential for stationary applications, where fuel cells need to deliver high current densities.

Solar energy

Heat buildup in solar thermal power plants is limited by thermal losses from the solar radiation absorber tube. As part of the LFR 500 project, IREIS developed a selective coating designed to reduce infrared radiation losses from the receiver.

The molten salts developed by IREIS for ion plasma nitriding have excellent thermal storage properties. Used in concentrated solar power plants, they store large amounts of thermal energy, which they release at night or during cloudy periods, allowing the plant to operate continuously.

Nuclear industry

Surface treatments are widely used in the nuclear industry. The engineers at IREIS conduct studies on the bearings of hydroelectric turbines, focusing on friction and sizing aspects.

We also design large-scale microwave plasma nitriding machines capable of treating long parts used in nuclear reactor instrumentation.

Process Industry

Parts used in the process industry are subjected to high mechanical stresses and must deliver optimal performance. Surface coatings enable materials to withstand these stresses, thereby extending the service life of industrial installations while reducing operating and maintenance costs, all while ensuring high production quality.

To this end, IREIS has developed advanced surface coatings that provide high-performance and durable properties, including:

- Gas filtration

- Barrier effect

- Anti-adhesive properties

- Wettability (hydrophobicity)

- Resistance to corrosion and extreme conditions

- Resistance to mechanical stress

- Catalytic and nucleation properties