tribological test bench

HEF Group, with its recognized expertise, takes into account a wide range of parameters such as materials (metals, polymers, ceramics), types of lubricants (oils, greases), and extreme operating conditions (pressures ranging from 10⁻⁵ mbar to 35 bar, temperatures from -200°C to +700°C, gaseous or liquid environments, and speeds reaching several tens of meters per second). In addition to these factors, contact geometry, applied loads, and surface properties (hardness, roughness, chemical composition, geometric defects, and affinity with the lubricant) also influence tribological behavior.

Shaft-Bearing system

The Shaft-Bearing system enables the characterization of friction and wear of materials or coatings in either dry or lubricated environments. It offers three possible test configurations: shaft/bearing, shaft/plate, and a fixed loaded shaft in contact with a rotating ring.

These configurations are suitable for studying hydrodynamic lubrication regimes. The equipment allows testing at rotational speeds of up to 10,000 rpm, with normal loads ranging from 500 to 20,000 N. It can accommodate shafts with diameters up to 30 mm, operates with oil temperatures up to 120°C, and uses approximately 1.2 liters of oil.

The system also enables control of the test sequence by varying the speed and/or the applied normal load.

Ring-on-Flat device

The Ring-on-Flat device enables wear and compatibility characterization of DLC (Diamond-Like Carbon) coatings in lubricated environments, using either base oils or fully formulated lubricants. It offers various contact configurations—ring-on-flat, cylinder-on-cylinder with parallel or crossed axes—allowing evaluation of the mechanical behavior of DLC layers and sublayers.

It is well-suited for tests replicating real-world cam/tappet or cam/follower contact conditions. The system operates with a ring rotational speed ranging from 10 to 3000 rpm, normal loads between 50 and 5000 N, and oil temperatures from 0°C to 120°C. It also supports reciprocating motion of the flat up to 20 mm at a speed of 60 mm/min, with an oil volume of 1.6 liters.

The setup is optimized to dissipate frictional power under conditions close to real applications.

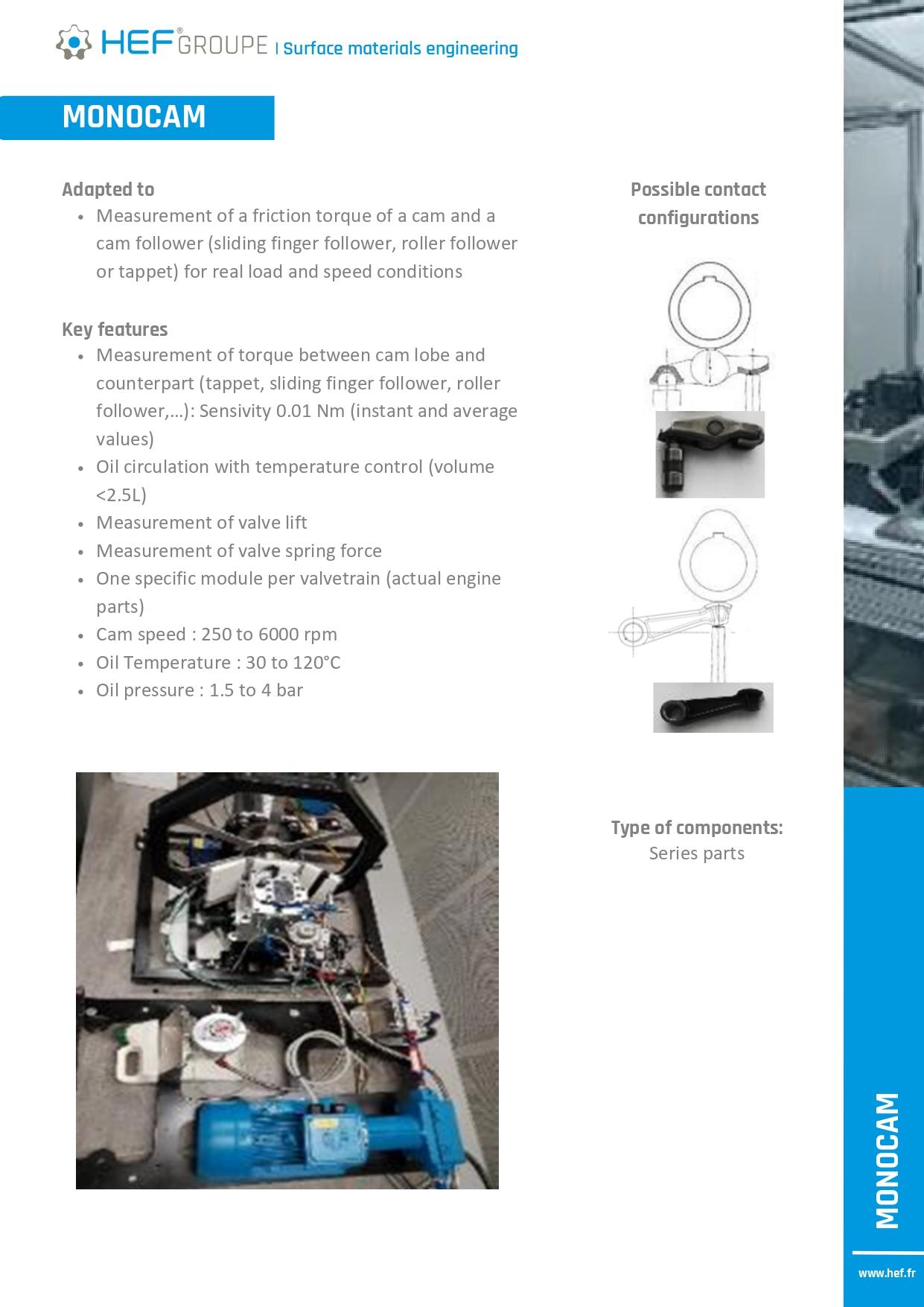

MONOCAM test bench

The MONOCAM test bench is designed to measure the friction torque between a cam and its follower (roller, tappet, or sliding finger follower) under real-world load and speed conditions. It evaluates the torque between the cam lobe and its counterpart with a sensitivity of 0.01 Nm, providing both instantaneous and average values.

The equipment includes an oil circulation system with temperature control (volume < 2.5 L), and also allows for the measurement of valve lift and valve spring force. Each module is dedicated to a specific valvetrain type, using actual engine components. The system supports cam speeds ranging from 250 to 6000 rpm, oil temperatures from 30 to 120°C, and oil pressures from 1.5 to 4 bar. It is specifically designed for the study of production parts under realistic engine operating conditions.

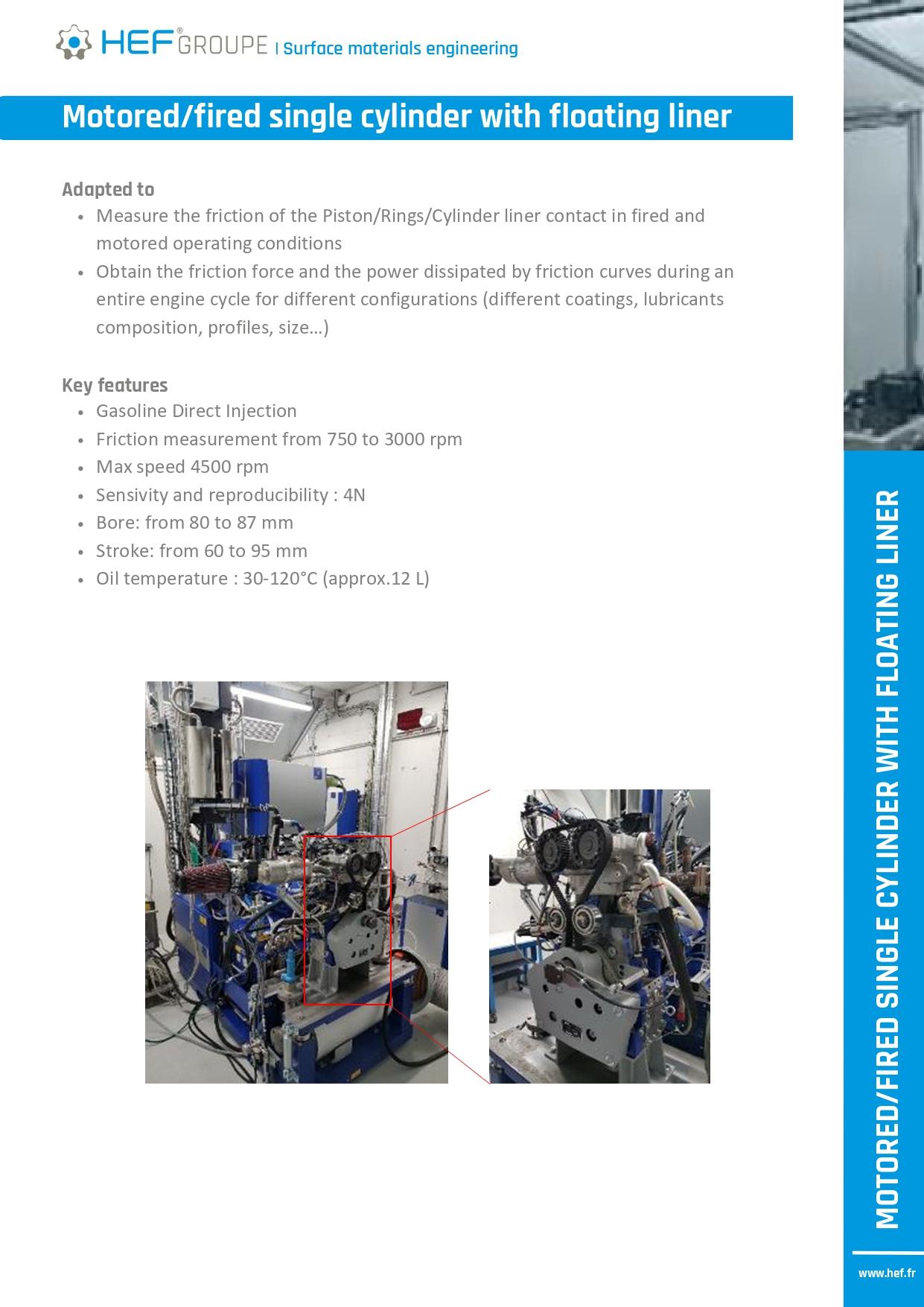

Single-cylinder test bench with floating liner

The single-cylinder test bench with floating liner is designed to measure friction forces between the piston, piston rings, and cylinder liner under real engine conditions (motored or fired). It enables the determination of friction forces and dissipated power throughout the engine cycle, depending on various parameters such as coatings, lubricants, geometries, and dimensions.

This bench uses a gasoline direct injection engine and allows friction measurements from 750 to 3000 rpm, with a maximum speed of 4500 rpm. It offers a sensitivity and repeatability of 4 N. The testable dimensions include bores ranging from 80 to 87 mm and strokes from 60 to 95 mm. Oil temperature is controlled between 30 and 120°C, with a total oil volume of approximately 12 liters.